Our Products & Services

At NEXTURE DYNAMICS, we offer a diverse range of CNC machining products and services designed to meet the needs of various industries.

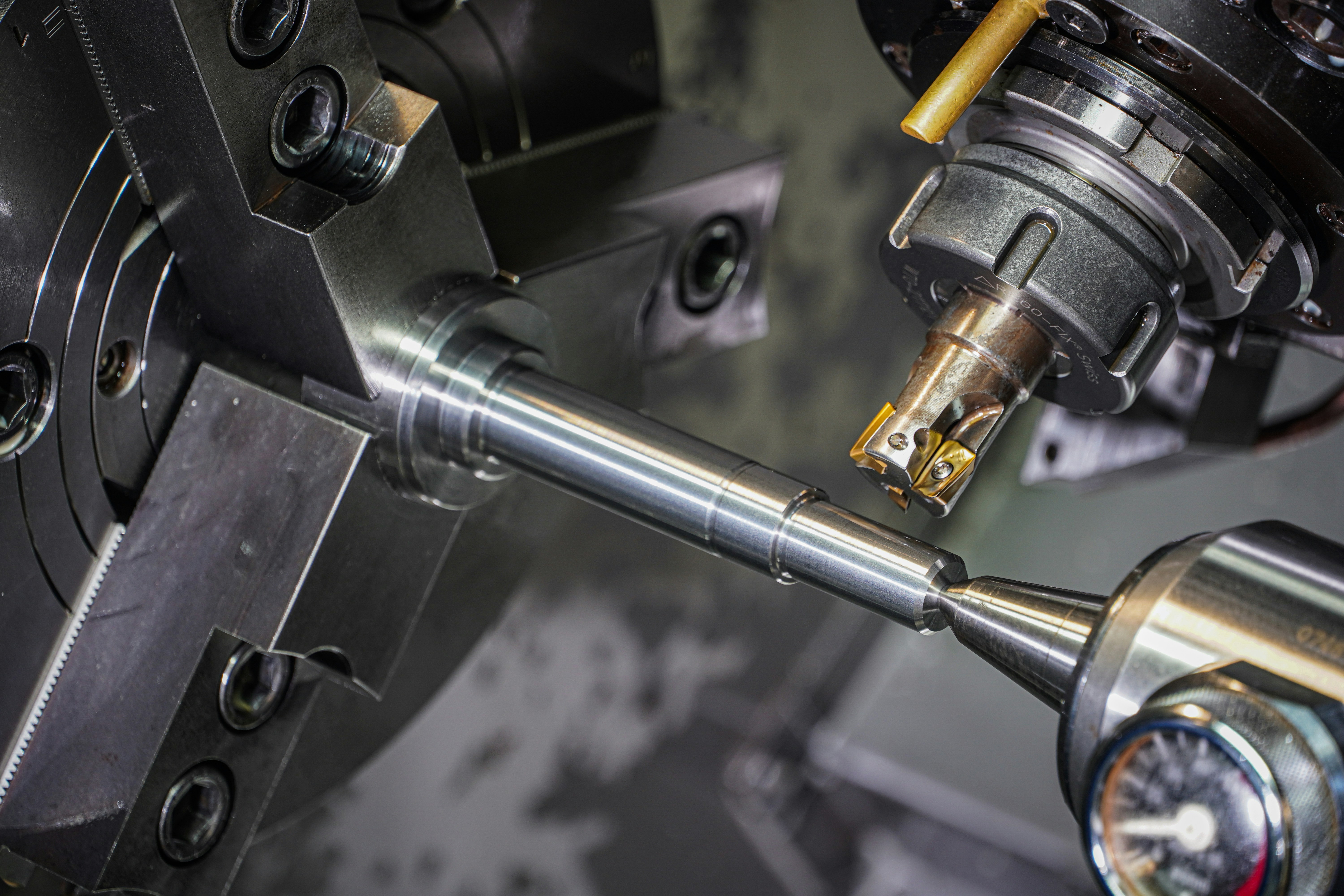

CNC Machining Services

Our milling services involve the precision cutting of materials to create complex shapes and detailed features. Ideal for prototypes and production runs.

MaterialAluminium, steel, titanium, plastics, and more.

Capabilities3-axis, 4-axis, and milling.

Using our CNC lathes, we produce cylindrical parts with tight tolerances and high-quality finishes. Perfect for shafts, bushings, and other rotational components.

MaterialStainless steel, brass, plastics, and more.

CapabilitiesStandard and complex turning operations Up to 500M.

Our grinding services offer superior surface finish and dimensional accuracy for precision components. Suitable for high-tolerance applications.

MaterialMetals and alloys. Collaborated with sister concerns.

CapabilitiesSurface grinding, cylindrical grinding, and more.

Our Wirecut services offer superior surface finish and dimensional accuracy for precision components. Suitable for high-tolerance application

MaterialMetals,alloys and more.

Aerospace Components

High-precision parts designed to meet the stringent requirements of the aerospace industry.

ExamplesAircraft brackets, engine components, landing gear parts.

Automotive Parts

Durable and accurate components for various automotive applications, including performance parts and OEM replacements.

ExamplesEngine components, transmission parts, custom brackets.

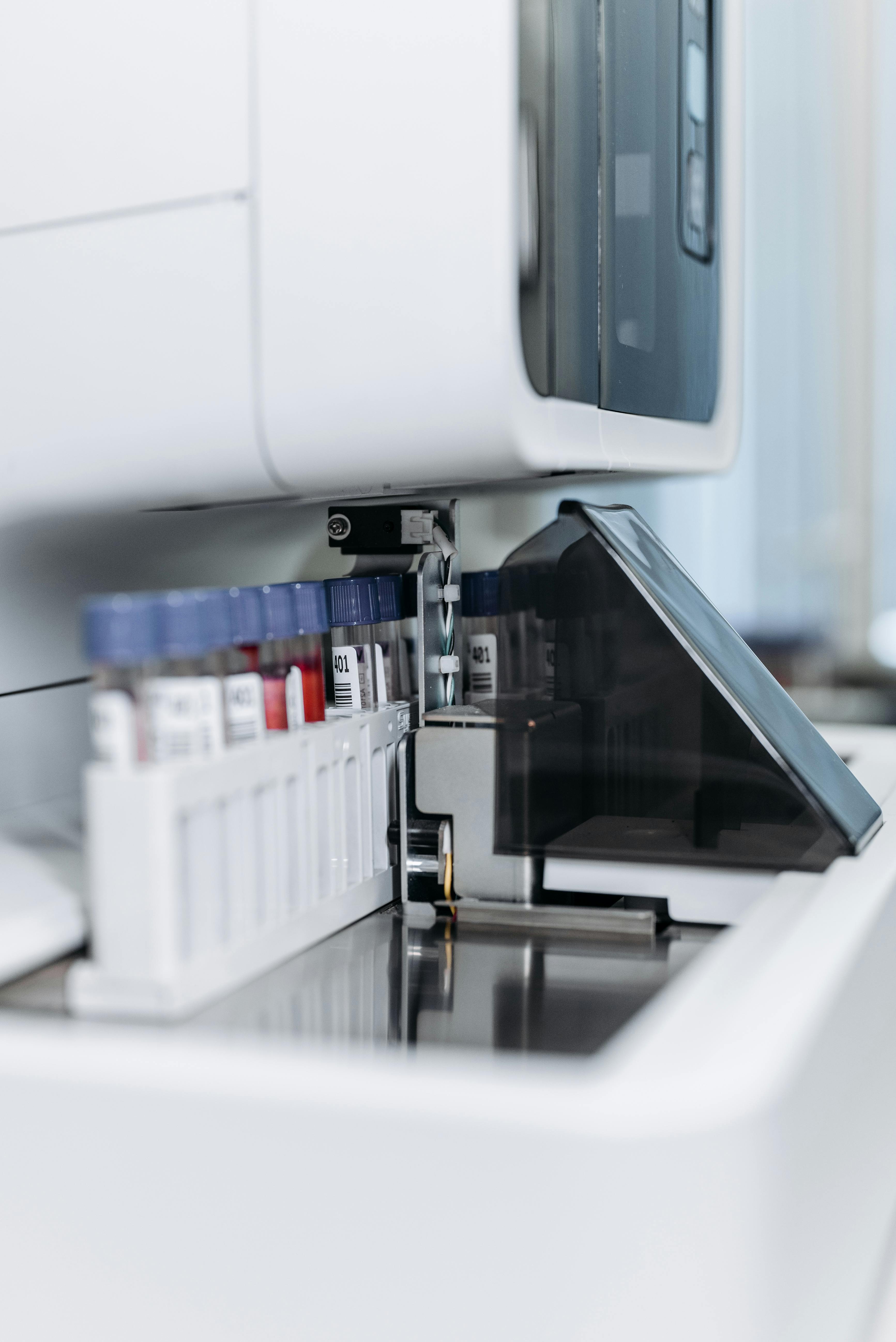

Medical Devices

Precision-engineered components for medical devices and equipment, adhering to strict industry standards.

ExmaplesSurgical instruments, diagnostic equipment parts, prosthetic components.

Industrial Equipment

Robust parts designed for industrial machinery and equipment, ensuring reliability and longevity.

ExmaplesGearboxes, valve components, custom fixtures.

Our Equipment

At Nexture Dynamics, we pride ourselves on using state-of-the-art equipment to deliver precision machining solutions. Our advanced machinery and technology enable us to handle a wide range of projects with exceptional accuracy and efficiency. Below is a list of the key equipment in our facility.

CNC Milling Machines

BFW BMTC2400

Description: Bed capacity upto 600mm with ATC Attached

Features: High-speed spindles, large worktable, 4th axis attached

Applications: For large milling complex parts

CNC Turning Centers

LMW LX20TL3 – LL20TL5

Description: Turning Diameter upto 350mm and travel upto 600mm

Features:Capability of turning long highly critical profiles

Applications: Long stem, automobile shafts and aerospace parts.

Grinding Machines

Description:Surface grinding upto 800mm long 400 mm width. With achievable tolerance upto 3 microns.

Features: Precision controls

Applications:Grinding of guideways and other similar blocks.

Additional Equipment

SPM Main hole

![[Equipment Name]](./Images/RK Images/spm main hole.jpeg)

Description: High speed drilling upto Dia 60mm and 600mm Long

Features: Double spindle Drilling mechanism

Applications: Drilling of long Shafts with high speed.

SPM Cross hole

![[Equipment Name]](./Images/RK Images/spm cross hole.jpeg)

Description: Drilling Diameter upto Dia 40mm and 400 mm long

Features: Double spindle servo drilling machine

Applications: used for drilling automotive parts used in propeller and coupling

Radial Drilling

![[Equipment Name]](./Images/RK Images/Radial-Drilling-Machine.png)

Description: Drilling Diameter upto Dia 40mm and 800 mm long with base of 500mm

Features: Vertical drilling at various locations

Applications: used for drilling valve parts , flanges and shafts.

Technology and Innovations

Designing and Drafting facilities

![[Technology]](./Images/RK Images/Design and draft.jpg)

Description: We can develop the holding fixture for you with the whole process development

Benefits: The work holding will be easy and user friendly. The gauges and process paramaters all will be provided.

Our Commitment to Quality

At Nexture Dynamics, quality is at the core of everything we do. We understand that precision and reliability are critical in CNC machining, and we are dedicated to maintaining the highest standards in every aspect of our operations. From initial design to final delivery, our rigorous quality control processes ensure that every component we produce meets and exceeds industry standards.

Quality Assurance Process

1. Design Review

Description: Before production begins, our team reviews all designs and specifications to ensure they are feasible and meet client requirements.

Tools: [Software or tools used for design verification.]

2. Material Inspection

Description: We perform thorough inspections of all incoming materials to ensure they meet our stringent quality standards.

Methods: [Testing methods or certifications.]

3. In-Process Quality Control

Description: During manufacturing, we conduct real-time inspections and measurements to monitor quality and precision.

Equipment: [Inspection tools and machines used.]

4. Final Inspection

Description: After machining is complete, each part undergoes a final inspection to verify that it meets all specifications and quality criteria.

Techniques: [Inspection techniques and equipment.]

5. Testing and Verification

Description: We conduct additional testing as required, including functional tests and stress tests, to ensure performance and durability.

Standards: [Industry standards and benchmarks used.]

6. Documentation and Reporting

Description: Detailed reports and documentation are maintained for each project, ensuring traceability and accountability.

Tools: [Software or systems used for documentation.]